Tailor-made or at catalogue solutions

AceLabs excels in the design and manufacture of higlhy specialized and customized to address tha lack of standards and solutions to enable its customers to operate even in the presence of a fault condition, which would render ineffective the common systems on the market.

AceLabs excels in the design and manufacture of higlhy specialized and customized to address tha lack of standards and solutions to enable its customers to operate even in the presence of a fault condition, which would render ineffective the common systems on the market.

In this regard AceLabs is proud to propose some solutions customized according to the specific needs of some of our customers like Bvlgari Gioielli Spa, Memc Electronic Materials Spa and Cugher Glass Srl.

The technological and manufacturing facility of AceLabs in the mechanical and electronic field possible to cut down the time to market of the systems offered, ensuring total control over the entire development of the project.

The company has significant experience in the implementation of illuminators, designed and vertically oriented on the need of each customer while maintaining equitable threshold of investment required.

The success of the solutions proposed by AceLabs stems from a thorough understanding of customer needs and technological process of production to be measured, inspected and tested.

- Inspection machines

-

Inspection machines for quality control based on artificial vision technologies

AceLabs produces at catalog for specific sectors, complete quality control machines, able to inspect every single piece in series or individually. The machines are modular and customizable.

AceLabs produces at catalog for specific sectors, complete quality control machines, able to inspect every single piece in series or individually. The machines are modular and customizable.

-

- Vision systems for manufacturers of industrial machines

-

Vision systems for manufacturers of industrial machines

AceLabs designs and manufactures on behalf of manufacturers of automatic industrial machines of any sector, artificial vision systems to be integrated into every product machinery, acting as a integrator and acting as a research and development specifically for vision.

AceLabs designs and manufactures on behalf of manufacturers of automatic industrial machines of any sector, artificial vision systems to be integrated into every product machinery, acting as a integrator and acting as a research and development specifically for vision.

-

- Vision systems for the end user

-

Vision systems for the end user

In any industry, it is increasingly crucial to have adequate inspection and control processes, those who have these needs are often end users.

In this case, AceLabs designs and manufactures artificial vision systems to be implemented in the machinery of the end user, studying how to adapt the solution to production.

-

AceLabs provides integration of the individual systems with the entire IT organization and management of its customers, including the systems of control and oversight.

AceLabs supports its clients in the analysis process, providing them with a service consulting and continuous side by side in the strategic decisions related to the production cycle.

From the idea to the machine in use

- Needs study

-

Needs study

Initial phase of analysis with the customer, the needs are assessed with an inspection in the plant, we evaluate the real possibility of adopting a vision system to understand how to better integrate the technologies in production.

Together with the customer we analyze the various solutions, proposing the most advantageous from the point of view of the plant as a whole.

-

- Technical/economic analysis

-

Technical / economic analysis

At this stage, as a result of the needs identified, it is formulated by the sales department with the collaboration of the technical office, an economic technical proposal without any commitment for the customer.

At this stage, as a result of the needs identified, it is formulated by the sales department with the collaboration of the technical office, an economic technical proposal without any commitment for the customer.In the proposal, a technical description of the proposed system or machine is presented with the related components and delivery times defined together with the customer.

-

- Design and construction

-

Design and construction

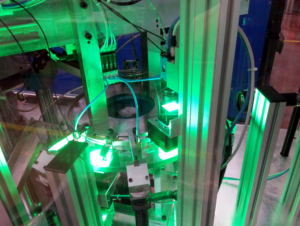

Mechanical production phase and software design, thanks to the close collaboration between the production department with CNC machines and the IT department, the algorithms for the vision system are chosen and designed, built on the specific mechanics and on the inspection requirements.

AceLabs following the many years of experience in the design of artificial vision algorithms, boasts a vast internal library.

-

- Installation and testing

-

Installation and testing

Once the internal production of the system/machine is terminated and internally tested, AceLabs delivers and installs, interfacing all the components with the customer’s infrastructure.

The most important phase is the calibration and the final testing, after specific tests carried out in the presence of the customer and after verifying the correct program functions, the test is signed and released to the customer for final use.

-

- After sales assistance

-

After sales assistance

The service of AceLabs does not end with the delivery, but the goal is to follow the customer with an highly qualified technical assistance service.

Among the services included there are: the guarantee on the functioning of the product, the warranty on the components and the technical assistance activities.

AceLabs offers its customers, for the period after the warranty coverage of the products, different types of service and maintenance contracts (scheduled, in token or custom).

Depending on the specific needs, AceLabs is able to offer the maintenance of a dedicated spare parts warehouse that guarantees immediate procurement times for companies operating in a continuous cycle.

-

also in: Italian

English

English