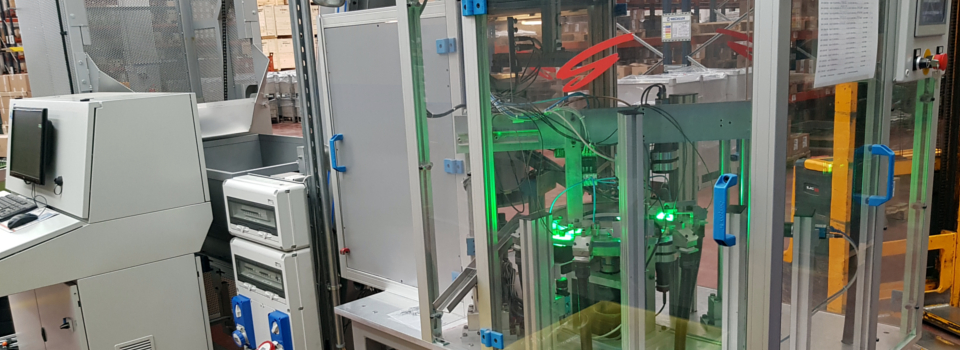

Automatic inspection and sorting machine

AceSDC is an inspection machine that allowsto check the quality and tolerances by selecting the parts according to the Good/Waste logic through highly sophisticated inspections in the shortest possible time.

The automation of the machine consists of a scale conveyor belt that allows the pieces to be inserted into a vibrating (soundproof) bell, which in turn allows access to the viewing chamber consisting of cameras and a rotating tempered glass plate on which the pieces circulate. The vision system is managed by a computer, which makes it possible to display the acquired images of each single piece, in several positions, elaborating the inspection statistics and the relative tolerance margins.

The high versatility of the machine and the algorithms in the vision system software, allow to control small parts of every type or dimension, with the possibility to add or insert a number of cameras or illuminators, variable for each type of piece to be analyzed. The final result of the work of AceSDC, will be the supply of selected pieces in good/waste and automatically divided into separate containers.

- Features

- Glass structure to control the process externally

- Piece presence sensors

- Hopper for separator, slides and tilt soundproof

- Controlled and adjustable air ejectors

- Expulsion and collecting nuts for good / waste parts

- Fill time, 1 hour (customizable by cycle time)

- Reading and selecting codes on a piece

- 1.3 MPixel monochrome digital cameras (customizable)

- Macro and telecentric optics

- Illuminators adaptable to any type of piece and material

- Display statistics and monitor tolerance

- Full HD monitor with keyboard/touch, implementation in the machine (optional)

- Monitor display of all images acquired in several different inspections

- Options and commands that can be called via simple icons

- Generate result files with statistics

- Storing all images in compressed images

- Remote Assistance: the system is set up to have remote support via a dedicated VPN connection.

- Advantages

- Risk reduction and control increased batch tolerances

- Short setup times

- Multiple checks in an instant

- Intuitive operation thanks to the simple interface

- Reduction of visual fatigue to the operator

- Productivity increased

- Functions

- Aesthetic surface control

- Assembly check/verification

- Metrology of the piece

- Reading codes in general on the piece

- Application areas

- Automotive

- Faucets, Valves, Racorderia

- Electronics

- Small mechanical parts

- Product details

-

- Video

also in: Italian

English

English